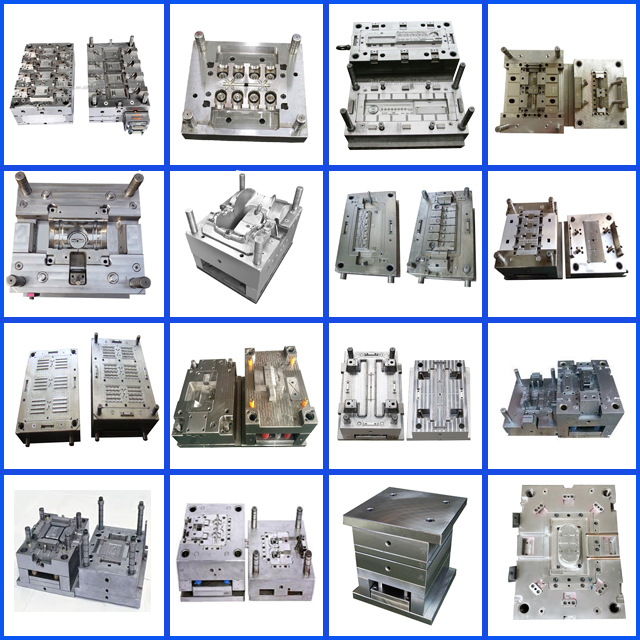

In the injection molding industry, the choice of mold is crucial to production efficiency, product quality and manufacturing costs. In order to help companies choose the right mold for different production needs, SPI (Society of the Plastics Industry) mold classification provides a standardized way. The SPI mold classification system divides the mold into four grades: Class 101, Class 102, Class 103 and Class 104, based on the design accuracy, surface treatment, durability and production cycle of the mold.

Class 101 stands for the highest grade of mold and is typically used for high-precision, high-volume production. The design and processing requirements of this type of mold are extremely high, and can withstand millions of production cycles, and are often used in precision electronic parts, automotive parts and high-quality consumer goods. The Class 101 mold steel is made of high-quality steel with strong wear and corrosion resistance, such as S136 or H13, and the surface treatment is required to reach the mirror polishing level. Despite its high manufacturing costs, it is suitable for mass production due to its excellent durability and production efficiency.

Class 102 molds are suitable for medium batch production with slightly lower precision and surface requirements than Class 101, but still have high quality standards. It is often used in the production of medium complexity plastic parts such as household appliance parts and automobile shells. The Class 102 mold usually uses P20, 718 and other steels, and the surface treatment is relatively simple, which can maintain good working performance in hundreds of thousands of production cycles.

In contrast, Class 103 is a basic mold suitable for low to medium batch production, with relatively low design and accuracy requirements. This kind of mold is often used for the production of disposable products or simple daily plastic parts, mold steel is mostly selected P20 or 718 with low cost, simple surface treatment, short production cycle, and suitable for rapid manufacturing.

Finally, the Class 104 mold is an economical mold that is suitable for very low production volumes with minimal accuracy requirements. This kind of mold is mainly used for low-cost disposable plastic products, the production cycle is short, the manufacturing cost is lowest, but the mold life is relatively short. Class 104 molds are suitable for rapid mass production of simple or single-use products.

Through the SPI mold classification standard, manufacturers can choose the most appropriate mold grade according to the production requirements of the product, batch size, precision needs and budget situation. High-precision, mass-produced products are suitable for Class 101 molds, while for low-cost, low-precision production, you can consider Class 103 or Class 104 molds. Reasonable mold selection can not only optimize the production process, improve product quality, but also effectively control production costs.

Post time: Jan-03-2025