With the introduction of advanced technology in 2024, the sheet metal stamping industry has achieved a major breakthrough. This innovative approach revolutionizes traditional approaches to sheet metal stamping die technology, delivering a host of benefits and advancements that change the manufacturing landscape.

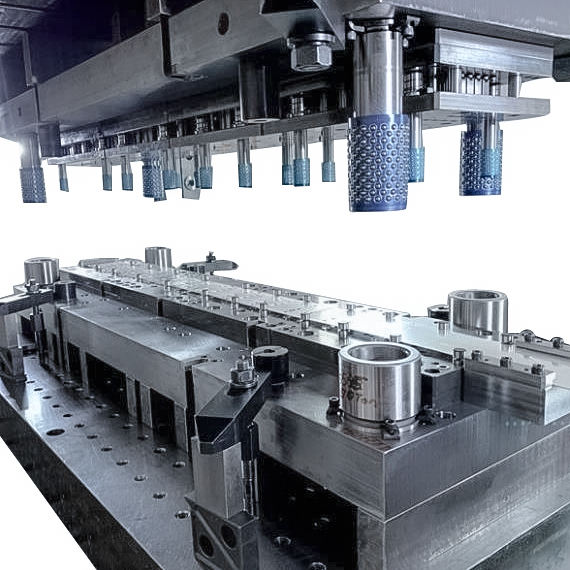

2024 Advanced Technology represents a leap forward in sheet metal stamping die design and production. This cutting-edge approach combines state-of-the-art materials, precision engineering and advanced manufacturing processes to create efficient, durable stamping tools. The use of advanced materials such as high-strength alloys and composites has significantly improved the performance and life of stamping dies, thereby increasing productivity and cost-effectiveness for manufacturers.

One of the key advantages of 2024 Advanced Technology is the ability to produce complex and complex sheet metal parts with unparalleled precision and accuracy. Advanced design and manufacturing processes enable the creation of complex mold shapes and configurations, enabling the production of highly detailed and precise sheet metal parts. This level of accuracy is critical for industries such as automotive, aerospace and electronics, where tight tolerances and complex designs are key requirements.

In addition, 2024 advanced technology also solves the problem of tool wear and maintenance in the production of sheet metal stamping molds. The use of advanced materials and coatings significantly reduces stamping die wear, extending die life and reducing maintenance requirements. This creates cost savings for manufacturers as they can now produce high-quality sheet metal parts with minimal downtime and maintenance costs.

In addition to improved performance and durability, 2024 Advanced Technology also improves process efficiency and cycle times. Innovative design and manufacturing processes optimize the stamping die production process, resulting in shorter cycle times and higher output. This allows manufacturers to meet the growing demand for sheet metal parts more efficiently, resulting in shorter lead times and higher customer satisfaction.

The introduction of advanced technologies in 2024 has also had a significant impact on the environmental sustainability of sheet metal stamping die production. The use of advanced materials and manufacturing processes reduces material waste and energy consumption, helping to achieve a more sustainable and environmentally friendly manufacturing process. This is becoming increasingly important in today’s industry as manufacturers strive to minimize their impact on the environment and adopt more sustainable production practices.

Overall, 2024 Advanced Technology represents a major breakthrough in the field of sheet metal stamping die technology. Its innovative approach redefines the functionality of stamping dies, improving performance, durability and efficiency. As manufacturers continue to adopt this advanced technology, the industry can expect to see further advancements in sheet metal stamping die production, resulting in increased productivity, cost savings and environmental sustainability.

Post time: Aug-29-2024