Die stamping, also known as die stamping, is a manufacturing process that uses sheet metal to create parts and components. It involves the use of a stamping die, a specialized tool that shapes and cuts metal into the desired shape. Stamping molds are vital components in the mold stamping process, and their structure and use play a decisive role in the quality and efficiency of the m

anufacturing process.

With more than 20 years of mold processing experience, our company has become a leading provider of custom mold stamping solutions. We have the professional knowledge to carry out customized processing according to the drawings provided by customers, or we can design the drawings ourselves. Our team consists of experienced mold designers who are skilled in creating efficient and reliable stamping mold structures for a variety of applications.

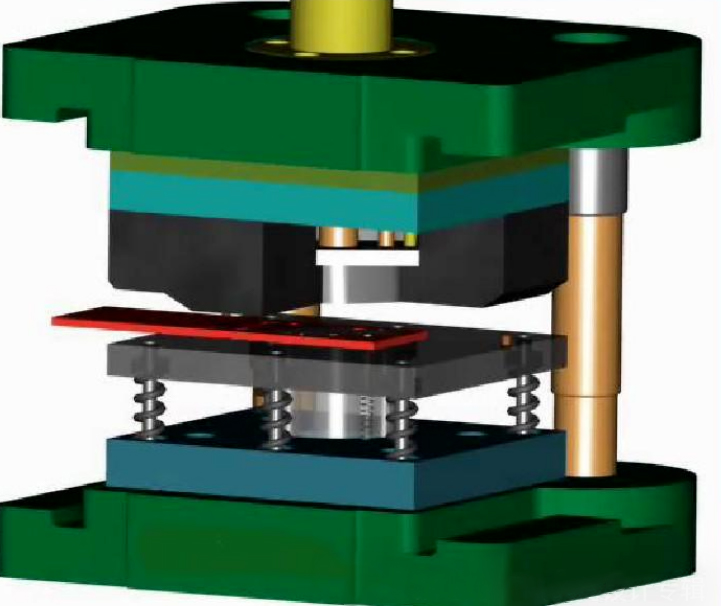

Stamping dies are constructed to withstand the forces and pressures involved in the stamping process. It typically consists of multiple components, including punches, dies, and strippers, which work together to shape and cut metal. The punch is the component that applies force to the metal, while the die provides the necessary support and guidance for the metal to be formed. After the stamping process is complete, an ejector helps remove the finished part from the mold.

The use of stamping dies is critical to achieving accuracy and consistency in die stamping. Molds are carefully designed to ensure that the metal is formed with the required precision and quality. By using carefully designed stamping dies, manufacturers can produce parts with tight tolerances and smooth surfaces that meet the precise specifications required by customers.

In addition to its structural importance, the use of stamping dies also helps improve the efficiency of the manufacturing process. With proper mold design, manufacturers can optimize production cycles, reduce material waste, and minimize the need for secondary operations. This saves costs and shortens lead times, making die stamping an attractive option for high-volume production.

At our company, we understand the importance of stamping die construction and use in achieving superior die stamping results. Our experienced mold designers use their expertise to create innovative mold structures that suit our customers’ specific needs. Whether it is a simple or complex stamping die, we are committed to providing solutions that meet the highest quality and performance standards.

In summary, die stamping and the structure and use of stamping dies are integral aspects of the manufacturing process. With our rich mold processing experience and professional mold design team, we are capable of providing customized stamping mold solutions to meet the diverse needs of our customers. By utilizing the latest technology and industry best practices, we strive to provide efficient, reliable and cost-effective die stamping services that exceed expectations.

Post time: Jun-05-2024