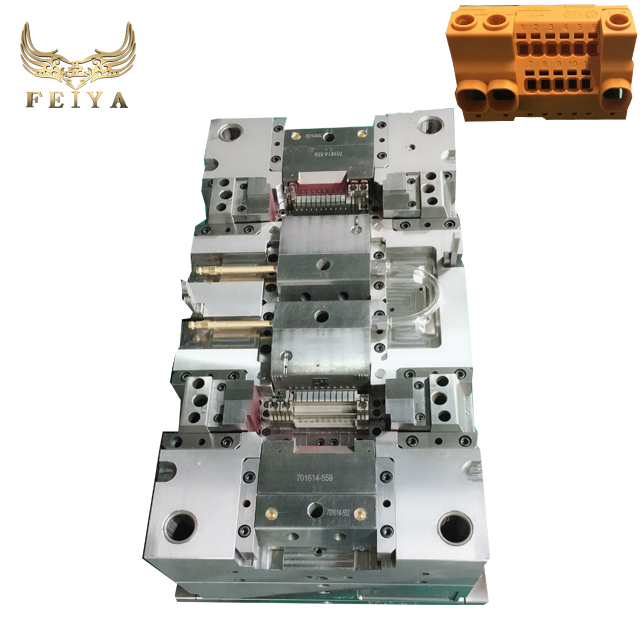

OEM Plastic injection mould primary circuit connectors

Product Parameters

|

Product name |

OEM Plastic injection mould primary circuit connectors |

|

Plastic material |

PP, PPA, ABS, PE, PC, POM, HDPE, etc. |

|

Steel of cavity and core |

Depend on product, we help customer to choose the suitable material. |

|

Steel of mold base |

Depend on product, we help customer to choose the suitable material. |

|

Mould Standard components |

HASCO, MISUMI, Meusburger, DME, etc. |

|

Runner |

1.Hot Runner: (Synventive from Netherland) or as your requests. |

|

Mold life |

Depends on the steel material and your requests. |

|

Surface finish |

Depends on your requirements. |

|

Delivery time |

Depends on the size and structure. |

|

Terms of payment |

T/T, L/C, Western Union, D/A, D/P, Paypal. |

|

Machine center |

High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

|

R&D |

1. Drawing design and making for products and mold; |

|

Production |

Pilot Run production and molding production can be provided. |

Product Description